Six Sigma DMAIC Green Belt Training Slides

Six Sigma DMAIC Green Belt Training Slides

Couldn't load pickup availability

Sigma is used to designate the distribution or spread about the mean (average) of any process or procedure

--

1,078 slides organized into 28 lessons (4 phase overviews) with 8 embedded Excel tools and instructions on creating numerous Excel tools from scratch. Download the Contents PDF for details.

Six Sigma DMAIC Green Belt training develops students into problem solvers—giving them the hard skills they need to lead successful improvement teams and achieve strategic objectives in any function or department. The Six Sigma Green Belt operates in support of or under the supervision of a Six Sigma Black Belt, analyzes and solves quality problems and is involved in quality improvement projects.

The Six Sigma Green Belt is a professional who is well versed in the Six Sigma Methodology who both leads and supports improvement projects, typically as a part-time role.

A Six Sigma Green Belt possesses a thorough understanding of all aspects within the phases of D-M-A-I-C. They understand how to perform and interpret Six Sigma tools and basic statistical analysis.

Six Sigma is a step-by-step process of interventions and statistical tools that allows companies to understand which business processes are not performing as needed, identify root causes of problems, analyze and improve contributing factors, and sustain gain in improvements.

Developed in the manufacturing industry and based on several time-tested existing quality measurement theories, Six Sigma is quickly gaining popularity in service industries, due to the breakthrough improvements and cost reduction it provides. Whether your company is large or small, whether it manufactures a product or provides a service to its customers (or a little of both), it can benefit from the tools and techniques of Six Sigma.

- A clear focus on achieving measurable and quantifiable financial returns from any Six Sigma project.

- An increased emphasis on strong and passionate management leadership and support.

- A clear commitment to making decisions on the basis of verifiable data and statistical methods, rather than assumptions and guesswork.

The Six Sigma family of methodologies is widely acknowledged as being robust and effective for solving process problems and designing/improving products. A drawback to its adoption is the presumption that it requires expensive software tools and is too complex for many organizations.

This DMAIC Green Belt course disproves that assumption by providing sophisticated but understandable formulas, explanations and examples along with instructions on using the Microsoft Office Excel software (or similar suites) already available on almost all personnel computing devices to build simple but completely functional templates that can be used and reused on all of the organization’s projects. Some lessons include one or more Excel tools with samples and user guidance embedded in the PowerPoint file that can be used again and again on projects and daily operations.

Package provides a reprint license for up to 50 hardcopies and, where tools are embedded, permission to distribute up to 50 copies to students of the lesson. An unlimited reprint/duplication license is also available.

Summary

- All the products and services we produce have a certain amount of variation which can and do produce defects.

- Given the many times we repeat processes, these defects can be very harmful.

- Six Sigma is a method of viewing these produces statistically and from the points of view of our customers.

- By using Six Sigma tools, one of which is DMAIC, we can analyze and improve many of our processes, resulting in customer satisfaction and organizational success.

- Green Belt training prepares non-quality professionals to execute DMAIC projects.

| Phase | Lesson Name | Slides |

| Introduction | Course Introduction | 40 |

| Define | Identify Preliminary Requirements (CTQs) | 20 |

| Tool training | Voice of the Customer | 63 |

| Define | Initiate Six Sigma Project | 28 |

| Define | Define High Level Process Map | 33 |

| Measure | Measure Overview | 14 |

| Measure | Select CTQ Characteristics | 40 |

| Tool training | Quality Function Deployment (QFD) and Failure Modes and Effects Analysis (FMEA) Tools | 62 |

| Measure | Define Performance Standards | 20 |

| Tool training | 7 Process Improvement Tools | 55 |

| Measure | Establish Data Collection Plan & Measurement System Analysis | 65 |

| Tool training | Gauge R&R and Attribute R&R | 43 |

| Analyze | Analyze Overview | 12 |

| Analyze | Establish Process Capability | 63 |

| Analyze | Define Performance Objectives | 27 |

| Analyze | Identify Variation & Waste Sources – Part I | 31 |

| Analyze | Identify Variation & Waste Sources – Part II | 69 |

| Tool training | Change Acceptance Management | 60 |

| Improve | Improve Overview | 22 |

| Improve | Experimenting & Piloting | 79 |

| Improve | Confirm Solution, Set Tolerances & Document | 69 |

| Control | Control Overview | 18 |

| Control | Confirm Measurement System & Solution | 16 |

| Tool training | Project Solution Recommendation Package | 34 |

| Control | Build Process Control Plan | 66 |

| Control | Transfer Solution to Owner and Close Project | 29 |

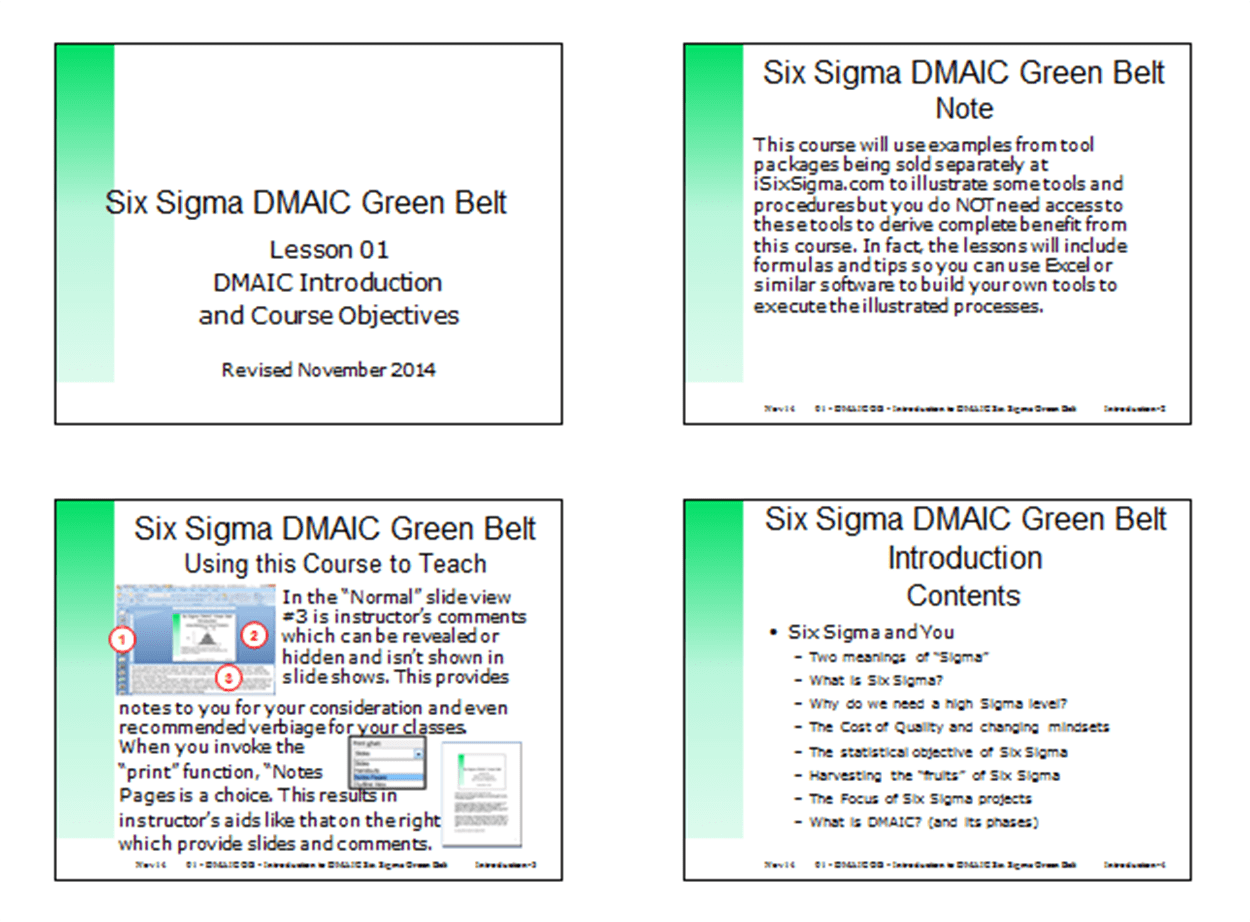

[caption id="attachment_17519" align="alignnone" width="1250"]

Sample image for training slides[/caption]

Sample image for training slides[/caption]

Open Source Six Sigma

More products from iSixSigma