Reducing Waste on Chicken Nugget Line Project Example

Reducing Waste on Chicken Nugget Line Project Example

Couldn't load pickup availability

Kahiki Foods Six Sigma project are expected to reduce daily waste percentage to 7.39 and save $178,042 annually

--

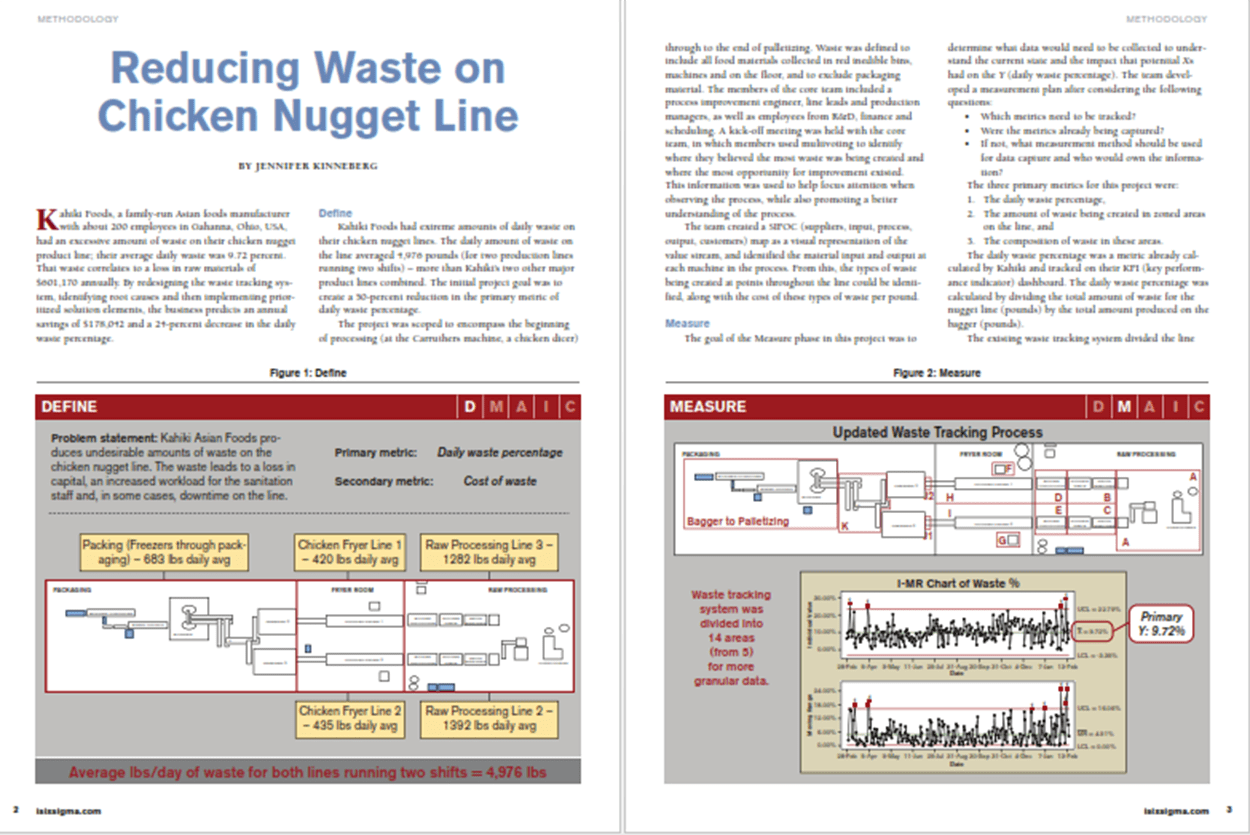

Kahiki Foods, a family-run Asian foods manufacturer with about 200 employees in Gahanna, Ohio, USA, had an excessive amount of waste on their chicken nugget product line. That waste correlates to a loss in raw materials of $601,170 annually.

By redesigning the waste tracking system, identifying root causes and then implementing prioritized solution elements, the business predicts an annual savings of $178,042 and a 24-percent decrease in the daily waste percentage.

The project was scoped to encompass the beginning of processing through to the end of palletizing. The members of the core team included a process improvement engineer, line leads and production managers, as well as employees from R&D, finance and scheduling.

Read the full report to find out more! The report is structured as it would be presented to a panel of company executives at the final project review.

The objectives of such a presentation are to communicate significant results of the project and share highlights of how results were achieved.

[caption id="attachment_17147" align="alignnone" width="1250"] Sample image for project example[/caption]

Sample image for project example[/caption]

Open Source Six Sigma

More products from iSixSigma