Reducing Turnaround Time of Lab Reports in the ICU Project Example

Reducing Turnaround Time of Lab Reports in the ICU Project Example

Couldn't load pickup availability

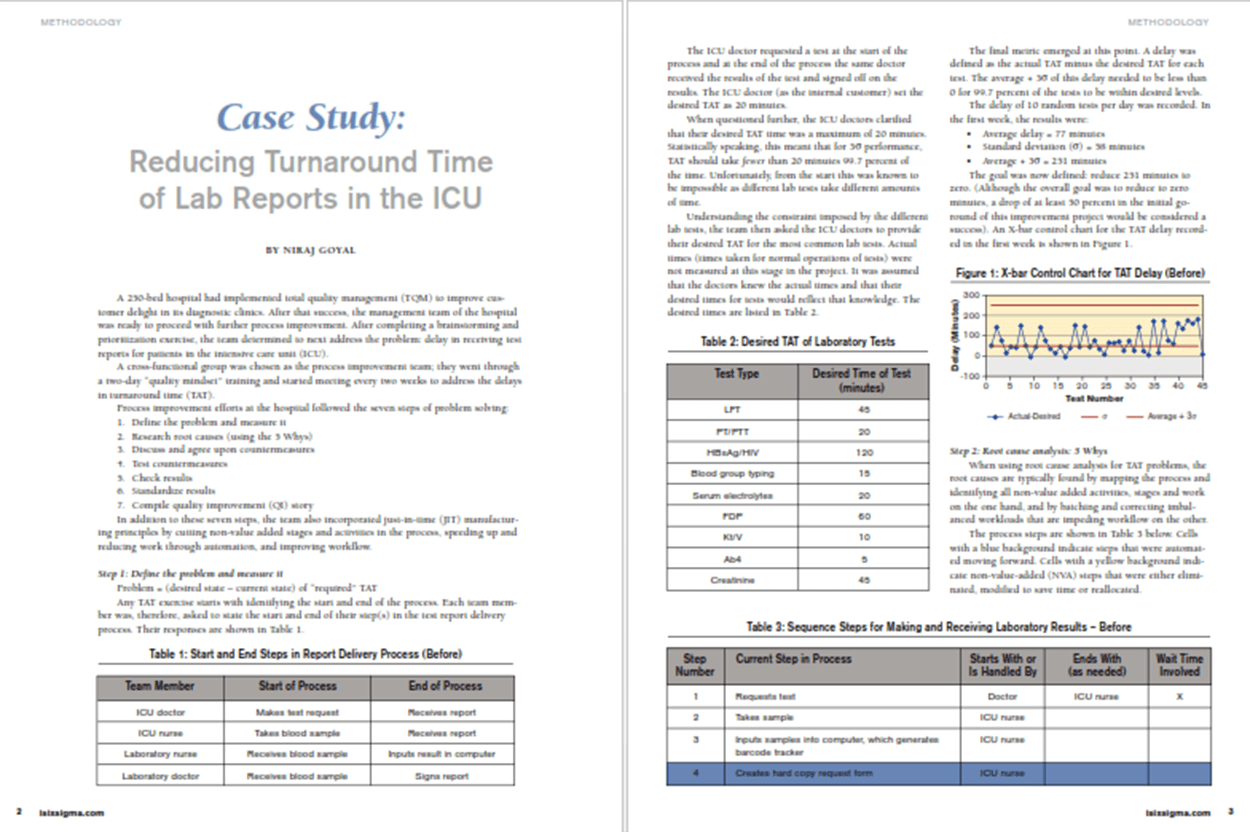

Lab Reports Six Sigma project resulted in 50% completed average delay on time and a maximum delay of 40 minutes/test

--

A 250-bed hospital had implemented total quality management (TQM) to improve cus- tomer delight in its diagnostic clinics. After that success, the management team of the hospital was ready to proceed with further process improvement.

After completing a brainstorming and prioritization exercise, the team determined to next address the problem: delay in receiving test reports for patients in the intensive care unit (ICU).

A cross-functional group was chosen as the process improvement team; they went through a two-day "quality mindset" training and started meeting every two weeks to address the delays in turnaround time (TAT).

Process improvement efforts at the hospital followed the seven steps of problem solving. In addition to these seven steps, the team also incorporated just-in-time (JIT) manufacturing principles by cutting non-value added stages and activities in the process, speeding up and reducing work through automation, and improving workflow.

[caption id="attachment_17184" align="alignnone" width="1250"] Sample image for project example[/caption]

Sample image for project example[/caption]

Open Source Six Sigma

More products from iSixSigma