Implementing 5S Training Slides

Implementing 5S Training Slides

Couldn't load pickup availability

5S is engage to workers in continuous improvement and promote workplace pride and ownership.

--

5S is a system to reduce waste and optimize productivity through maintaining an orderly workplace and using visual cues to achieve more consistent operational results. Implementation of this method "cleans up" and organizes the workplace basically in its existing configuration, and it is typically the first lean method which organizations implement.

5S is accomplished through the following phases:

- Sort (Seiri) - getting rid of what is unwanted and not needed anymore

- Straighten (Seiton) - designating the proper location for needed items

- Shine (Seiso) - clean and organize workplace

- Standardize (Seiketsu) - everyone doing and identifying things the same way

- Sustain (Shitsuke) - integrating 5S into the daily activities

The 5S phases provide a methodology for organizing, cleaning, developing, and sustaining a productive work environment. In the daily work of a company, routines that maintain organization and orderliness are essential to a smooth and efficient flow of activities.

This lean method encourages workers to improve their working conditions and helps them to learn to reduce waste, unplanned downtime, and in-process inventory.

Workplace organization is an important aspect of a continuous improvement program. An excellent 5S program will guarantee improved productivity and safety in your work environment.

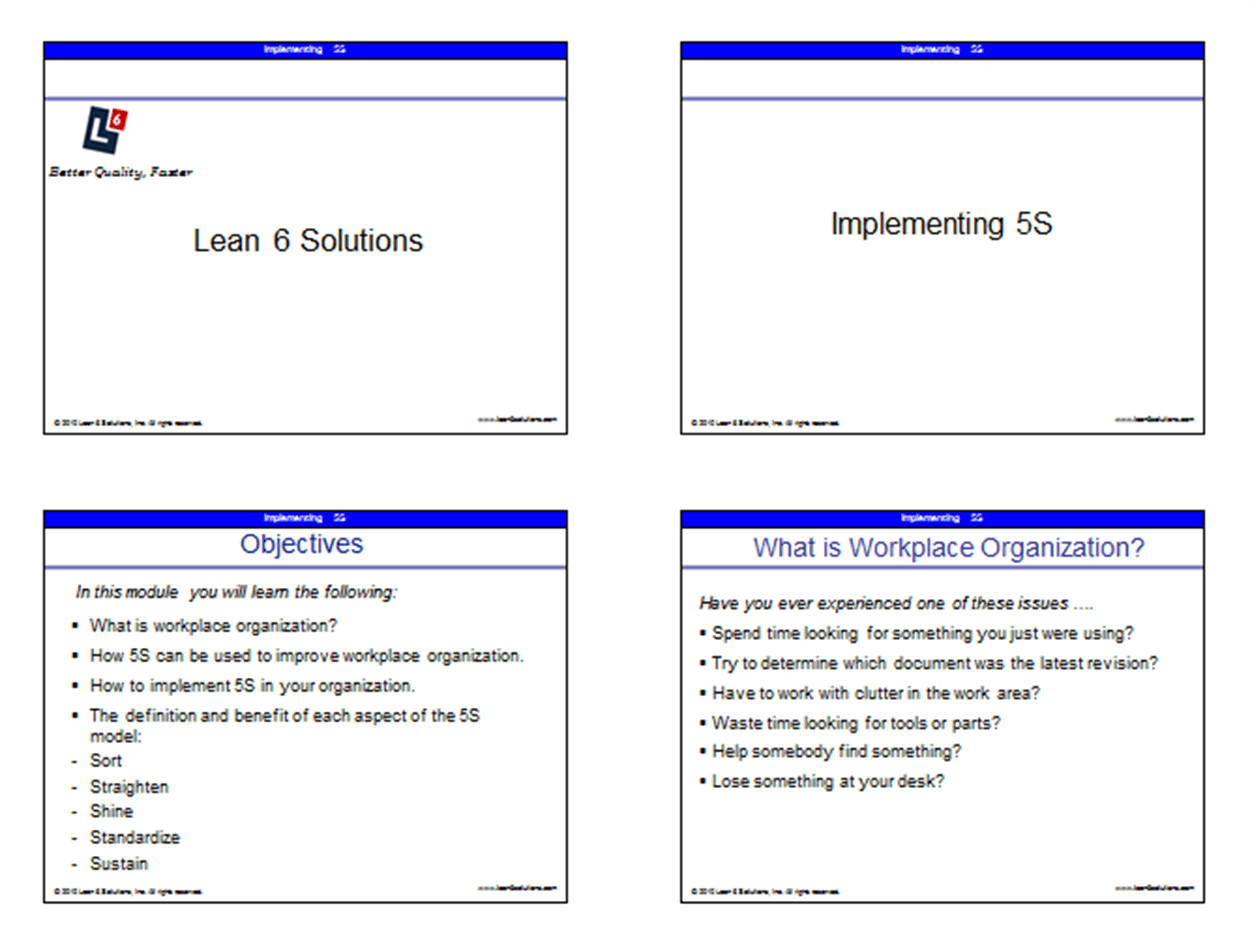

This course provides you with an overview of 5S, how it can benefit your company's performance, an explanation of each category, how to get started, and things to avoid.

In this course, you will learn:

- What is workplace organization?

- How 5S can be used to improve workplace organization.

- How to implement 5S in your organization.

- The definition and benefit of each aspect of the 5S model.

A 5S Template and a 5S Radar Chart to use during your implementations are included as part of this training course.

A typical 5S implementation would result in significant reductions in the square footage of space needed for existing operations. It also would result in the organization of tools and materials into labeled and color coded storage locations, as well as "kits" that contain just what is needed to perform a task.

Summary

- Workplace organization is an important aspect of a continuous improvement program.

- 5S means: Sort, Straighten, Shine, Standardize and Sustain.

- Measurement is a key component of a 5S program; develop a method to measure your results.

- An excellent 5S program will guarantee improved productivity and safety in your work environment.

[caption id="attachment_17492" align="alignnone" width="1250"]

Sample image for training slide[/caption]

Sample image for training slide[/caption]

Open Source Six Sigma

More products from iSixSigma